Fortifying steel for a resilient future.

For over four decades, World Tower has honed its expertise in durable infrastructure. We are proud to extend our commitment to longevity and quality with professional hot-dip galvanizing services for clients throughout Western Kentucky.

Our comprehensive process follows strict ASTM A123 specifications with comprehensive documentation and testing to ensure compliance with engineering requirements to deliver a consistent, high-quality zinc coating that provides 50+ years of maintenance-free corrosion protection, even in coastal and industrial environments.

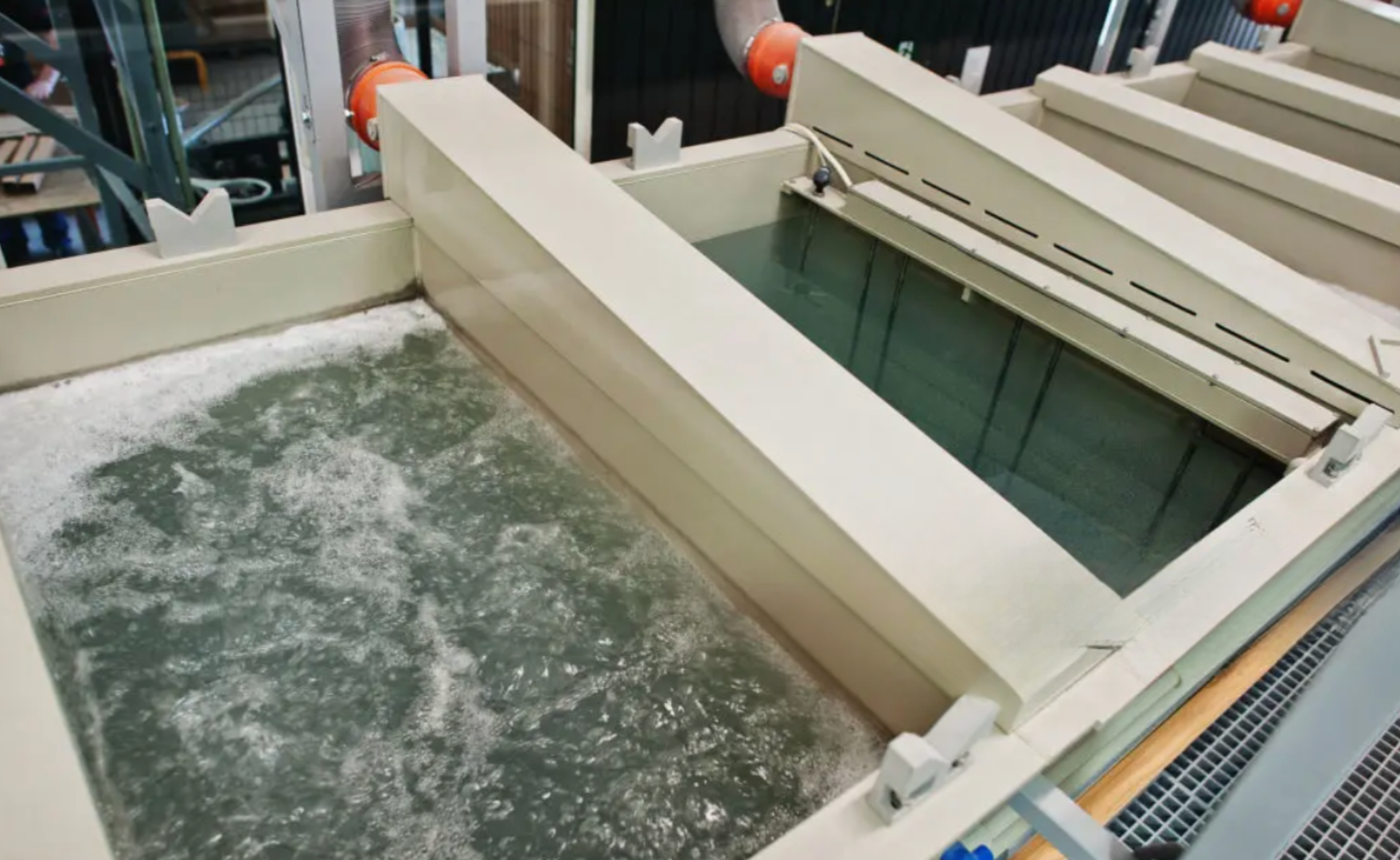

Unlike paint, which sits on the surface, our hot-dip galvanizing process creates a metallurgical bond with the steel at 3,600 psi, forming a durable alloy layer. The complete immersion in molten zinc at 840°F ensures thorough coverage of hard-to-reach areas, weld seams, and internal surfaces that other protection methods cannot adequately cover.

At World Tower, you'll have a direct connection to our team of experts, ensuring your project specifications are met with precision. Our unwavering dedication to the highest quality controls means your initial galvanizing investment pays for itself through eliminated maintenance costs and extended service life.

Experience the World Tower difference, where we don't just coat steel: we build a foundation of trust and reliability for every structure we help preserve.

GALVANIZING WITH WORLD TOWER

GALVANIZING WITH WORLD TOWER

Expert Hot-Dip Galvanizing Services Across Western Kentucky

Looking for galvanizing near you? Whether you're a fabricator in Paducah, a farmer in Mayfield, or a contractor in Hopkinsville, we have the capacity and expertise to handle your project. Contact us today for a quote on professional galvanizing services in Western Kentucky.

Graves County: Mayfield

McCracken County: Paducah

Calloway County: Murray

Marshall County: Benton

Ballard County: Wickliffe

Crittenden County: Marion

Fulton County: Fulton

Hickman County: Hickman

Christian County: Hopkinsville

Hopkins County: Madisonville

Carlisle County: Bardwell

Caldwell County: Princeton

Livingston County: Smithland

Trigg County: Cadiz

Lyon County: Eddyville